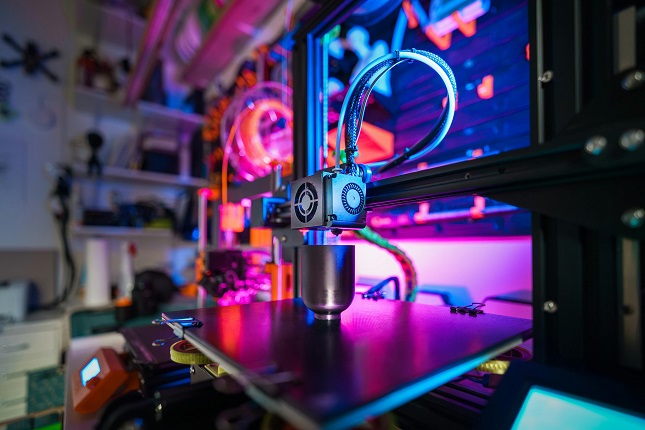

Diving into 3D printing with PETG filament can be a rewarding adventure, but it does come with its quirks. You’re not alone if you’ve ever struggled to get that perfect print. PETG is known for its strength and flexibility, making it a favorite among enthusiasts. But, achieving the best print quality requires a bit of know-how.

What is a PETG Filament?

PETG filament is a polyethylene terephthalate variant used in 3D printing. It combines the best features of ABS and PLA, providing both strength and flexibility. I remember my first print using PETG; it amazed me with its durability and smooth finish. Key benefits include chemical resistance, low shrinkage, and transparency.

High-Performance PETG Filament for Bambu Lab 3D Printers

PETG filament delivers impressive print results with Bambu Lab 3D printers. These machines bring out the best properties of PETG, which blend strength, flexibility, and ease of use.

Enhanced Durability and Flexibility for Various Projects

PETG filament’s strength shines in projects demanding durability and resilience. From personal experience, I printed a custom smartphone stand that survived several falls without a scratch. This incredible toughness and slight flexibility make PETG suitable for everything from mechanical parts to decorative items. Its chemical resistance adds another layer of value, which is optimal for creating components that need to withstand various environmental conditions.

Perfect Compatibility with Bambu Lab’s Advanced Printing Features

Bambu Lab printers work seamlessly with PETG filament. These printers excel with features like precise temperature control and adjustable fan speeds, which are essential for optimal PETG prints. I experimented with different settings and found consistent temperature and cooling, which resulted in fewer issues like stringing. This precision inspires confidence, especially for complex designs or delicate projects, as it manages the intricacies of PETG printing splendidly.

Why Choose Bambu Lab PETG Filament for 3D Printing?

Bambu Lab PETG filament delivers consistent results for new and seasoned users. Its versatility makes it a go-to for various projects, from intricate decor to functional prototypes.

Superior Print Quality for Professional and Hobbyist Use

Bambu Lab PETG filament stands out by offering top-notch print results. I once used Bambu Lab PETG to print a complex mechanical part. It came out with astonishing detail and a smooth finish. This filament’s reliable extrusion minimizes the chances of layer skipping or inconsistent layers. It’s ideal for projects demanding intricate detailing, making it perfect for both professional and hobbyist creations.

Heat-Resistant and Low-Warp for Precision Printing

Bambu Lab PETG is heat-resistant, withstanding temperatures up to 80°C, making it suitable for parts exposed to moderate heat. Its low-warp properties reduce the frustration of print failures. Adjusting to this feature, I printed a sturdy camera mount that maintained its shape even with continuous use and variable temperatures. These characteristics support precision printing, ensuring designs meet exact specifications even in demanding conditions.

Tips for Achieving the Best Print Quality with PETG Filament

PETG filament offers great print quality, but optimizing settings makes all the difference.

Optimal Temperature Settings

Printing with PETG requires the right temperature. Too low, and the filament won’t stick. Too high, and it can ooze. I find success with a nozzle temperature between 230°C and 250°C. The bed temperature should be around 70°C to 80°C. Always check the manufacturer’s guidelines as a starting point.

First Layer Adhesion

Adhesion to the first layer is crucial for the print’s foundation. A heated bed of 75°C works wonders for me. A clean glass surface or PEI sheet gives PETG a good grip. If warping troubles arise, a light coat of adhesive glue can help.

Retraction Settings

PETG filament tends to ooze, so retraction settings matter. To reduce stringing, set retraction distances between 4mm and 6mm. Speeds of 25mm/s to 30mm/s work well. I noticed fewer issues when I dialed these in. Testing with a small print can save headaches later.

Fan Speed and Cooling

Cooling plays a role in PETG’s finish. I keep my fan speed at 30% to 50%. Too much cooling makes layers brittle. I learned this during a phone stand project. Balancing cooling improved layer bonding, giving the stand the strength it needed.

Support Settings

Supports are essential for overhangs but tricky with PETG. Use lower densities, 10%-15%, to avoid filament sticking to supports. A gap of 0.2mm between the support and part helps remove them cleanly. Print settings like these prevent extra cleanup.

Filament Storage

PETG is hygroscopic, so store it well. Keep filament in a dry box with desiccants. I use vacuum-sealed bags for peace of mind. Dry filament means better prints and fewer issues. Invest in proper storage to maximize print quality.

Conclusion

And there you have it, fellow 3D printing enthusiasts! Mastering PETG filament might take a bit of trial and error, but with the right settings and a little patience, you’re on your way to producing durable, flexible, and beautiful prints. Whether you’re crafting intricate designs or tough, functional parts, PETG and your trusty Bambu Lab printer make a dynamic duo. Remember to dial in those settings, keep your filament dry, and enjoy watching your 3D creations unfold flawlessly. Happy printing!