Don’t let avoidable errors damage your next project!

Selecting transistors is a key step in the design of electronic circuits. Done right, it enables faster development and better performance. But with the power transistor market reaching $18.85 billion in 2024 and growing, it’s also more complex than ever before.

Table of Contents

Why getting transistor selection correct matters more than you think

Choosing the right transistor is more than just picking one that “works” on paper.

Neglecting component selection is the cause of numerous problems faced by engineers such as missed deadlines, cost overruns, and field failures.

The reality is that digital transistor market growth of 7.5% annually means there are more options than ever before to get wrong.

The consequences of making errors:

- Delayed delivery timelines

- Costly redesigns

- Complaints from customers about poor reliability

- Last minute scrambles to source components

Engineers working in the increasingly competitive electronics components market must take a more systematic approach to transistor selection, whether that is via traditional distributors or via new online electronic components sourcing platforms.

The 5 most important parameters you should never ignore

Voltage and current ratings are the obvious place to start when choosing a transistor. But there is a lot more to it than that.

The parameters that are most commonly overlooked:

Maximum Ratings and Safe Operating Area

It is not enough to meet just the normal operating conditions. Your transistor must also be able to survive the maximum conditions that will ever be seen.

Parameters to look at include:

- Collector-emitter voltage (VCEO)

- Collector current (IC)

- Power dissipation (PD)

- Safe operating area (SOA)

Pro tip: Always derate these specifications by at least 20% for a healthy safety margin.

Switching Characteristics

Speed is often more important than it first appears in modern electronics.

Things to consider:

- Rise time (tr)

- Fall time (tf)

- Storage time (ts)

- Maximum switching frequency

Thermal Performance

Heat is the number one killer of transistors.

You need to look at:

- Thermal resistance (both junction-to-case and junction-to-ambient)

- Maximum junction temperature

- Thermal cycling capability

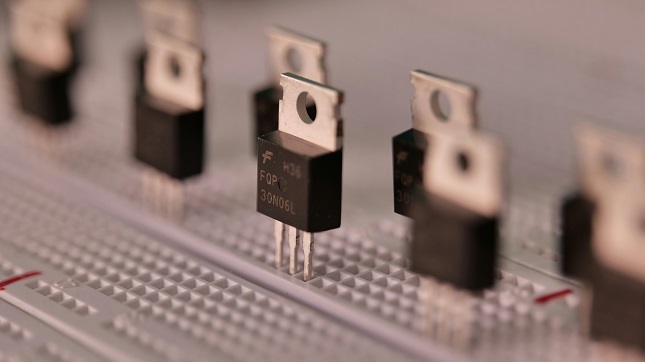

Package and Mounting Considerations

The package of the transistor can make a big difference in terms of thermal and electrical performance. Be sure to consider:

- TO-220 for high power

- SOT-23 for space constrained

- DPAK for surface mount power

Gain and Frequency Response

Current gain (hFE) is not constant and varies with both temperature and collector current. Do not assume a single value.

How to avoid the most costly mistakes

Time for some reality about selecting transistors:

Error #1: Selecting Based On Price

Low cost transistors often lead to expensive issues down the line. These components often have lower reliability, limited availability, or inconsistent performance.

Error #2: Not Checking Lifecycle Status

Engineers commonly make the mistake of selecting components without regard for end-of-life status. This leads to last minute redesigns when the parts are no longer available.

Error #3: Overlooking Environment Requirements

Design conditions aren’t the same as operating conditions. Consider all environmental factors:

- Operating temperature range

- Humidity

- Vibration and shock

- Radiation tolerance (for aerospace and similar)

Error #4: Not Planning For Second Sources

Parts with single suppliers are a recipe for disaster. It is imperative to have backup options available.

Error #5: Skipping Simulation And Prototyping

Assuming a transistor will work based on datasheet values is a fool’s game. Always prototype and test early.

Where to source components that you can rely on

Finding the right transistors is one thing, but having suppliers that can actually deliver on time is another.

Your sourcing strategy should include:

- Authorized distributors for authenticity guarantees

- Multiple sources to minimize risk

- Real time inventory visibility

- Lead time transparency

- Clear pricing

The key is to form partnerships with suppliers who understand your requirements and can support you for the long term.

Also, consider the global supply chain and geographical sourcing when needed.

Pro tips for future-proofing your designs

Want to be more resilient to transistor obsolescence and supply chain disruptions?

Follow these strategies that have been proven to work:

Design To Component Families

Rather than optimizing for a single part number, design to accommodate a family of transistors. This gives you more flexibility when it is time to source.

Monitor Trends

The semiconductor industry moves fast. Keep an eye on:

- New transistor technologies (e.g. GaN, SiC)

- Industry consolidation is impacting suppliers

- New applications driving demand

Build Margin Into Designs

Designing for more than the minimum specs costs more but avoids redesign expenses long term.

Establish Vendor Relationships Early

Don’t wait for a crisis to form supplier relationships. Talk to vendors early on.

Maintain Detailed Documentation

Keep a record of why you chose specific components. This will be critical during redesigns and when training new personnel.

Critical considerations for today’s applications

The electronics industry is different today than it has been in the past. This has an impact on what to consider when selecting transistors.

5G/high frequency:

- Transistors for RF performance are needed. Si BJTs won’t work in all cases – may require GaAs or GaN.

EV/electric vehicle:

- Transistors must be capable of withstanding high voltages and currents while maintaining efficiency. SiC MOSFETs are becoming a common choice here.

IoT/ battery powered:

- Power efficiency is of utmost importance. Select transistors with very low leakage current and fast switching speeds to minimize losses.

Mastering your selection process

The perfect process to get to the right transistor is a delicate balance between various factors such as performance, cost, availability and reliability.

The ideal strategy involves:

- Upfront, detailed requirements analysis

- Comprehensive parameter evaluation

- Risk assessment of supply chain issues

- Validation by prototyping before production

- Continuous monitoring of the components’ lifecycle

Selection is not a one and done process. Markets and technologies change, suppliers move in and out of business, and component lifecycles end. Engineers must stay involved in the selection process for their products for the long term.

Wrapping up your component strategy

Component selection has an impact on everything from product performance to manufacturing cost. Make good choices upfront to avoid major problems later on.

The landscape of electronic components is always changing, but the basics are the same. Understand your needs, compare options carefully and work with suppliers you can trust.

Most importantly, don’t rush it. The time spent during the selection process will be repaid many times over during the rest of the product lifecycle.

Ready to improve your component decisions? Begin by evaluating your current selection process and identifying where it can be improved to better mitigate risk and increase success.